Band heaters are tools that engineers use to heat parts in a specific area. A simple design, the band heater is almost always used in conjunction with

Band heaters are tools that engineers use to heat parts in a specific area. A simple design, the band heater is almost always used in conjunction with other types of heating methods.

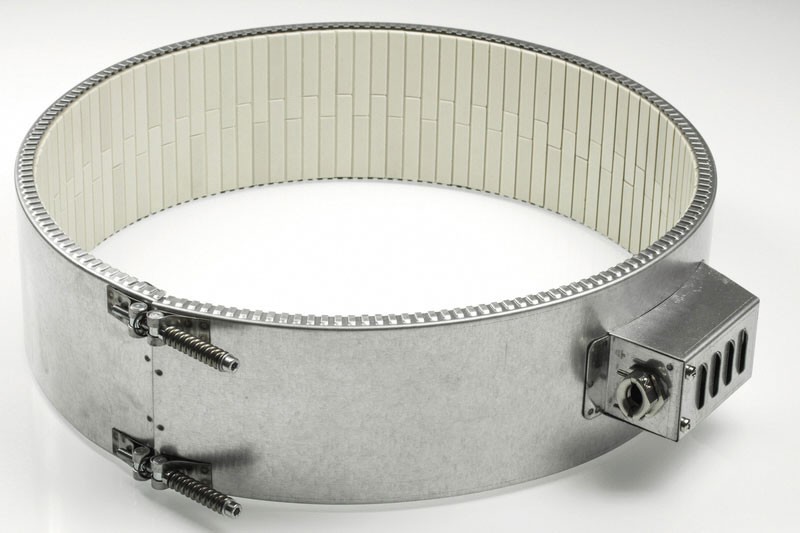

Bands come in many different diameters and metals. There are aluminum bands, steel bands, nickel alloy bands, copper alloy bands and more. Some can fit on hand-held tools, while others are built into the heating unit.

Induction Heating Band Heater

This type of band heater was developed by ERCO Worldwide Inc., a company that specializes in vacuum induction melting furnaces. Induction heating is typically used to heat small parts for welding or soldering, but it can also be used to heat larger parts that are placed nearby. The welders at ERCO reclaim precious materials by melting scrap metal into the induction heating band heater’s cold roll, which is then fed through a rolling mill to produce new stock.

The Induction Heating Band Heater uses electromagnetic induction to create an alternating magnetic field within its stainless steel bands. The alternating magnetic field heats the conductive metal directly underneath the band due to electromagnetic resistance, which in turn becomes hot enough for any welding or soldering job.

Read More: What is Air Handler and How It Can Cool Down the Temperature

Properties of Induction Heating Band Heater:

– Operates off a standard 110 volt outlet

– One set of bands will typically last a long time and can be replaced

– Even heating on small or large objects

– Heating area cannot be adjusted at the time of use

– Some models require a machine to operate, while others can be attached to a hand held device

Electrical Resistance Heat Band Heater

An electrical resistance heat band heater works by running an electric current through a flat metal band, causing it to heat up. These types of band heaters are typically used for spot heating an area on large objects, such as parts of a car or entire engines.

The Electrical Resistance Heat Band Heater consists of a metal band that is wrapped in an electrically resistant wire and covered in rubber insulation. The electric current heats the rubber and metal band, which in turn heats the object underneath it. The metal wire inside of the band can resist temperatures up to 1800 degrees Fahrenheit.

Properties of Electrical Resistance Band Heater:

– Operates off standard household electricity (110 volts)

– Easy to position and move around an area that needs heating

– Metal band cannot be replaced, so if it is damaged the entire band heater must be replaced

– Heating area cannot be adjusted at the time of use

– Some models require a machine to operate, while others can be attached to a hand held device

Resistance Spot Band Heater

Resistance heating bands are generally made out of nickel chromium wire. When electrical current passes through the wire it creates heat, which is then used to heat objects. Resistance heating bands are typically easier to use than induction heating band heaters, but they do not get as hot.

A Resistance Spot Band Heater contains a metal band that has nickel chromium wire running through it. The electric current heats the wire up, creating heat on one small part of the metal band. The rubber insulation on this type of band heater helps direct heat onto a targeted area.

COMMENTS